How To Repair Fiberglass Axe

How to replace a fibreglass maul handle |

|

| ||||

| Fibreglass handles should not be repaired they should be replaced. | |||

Things you volition demand: | ||||

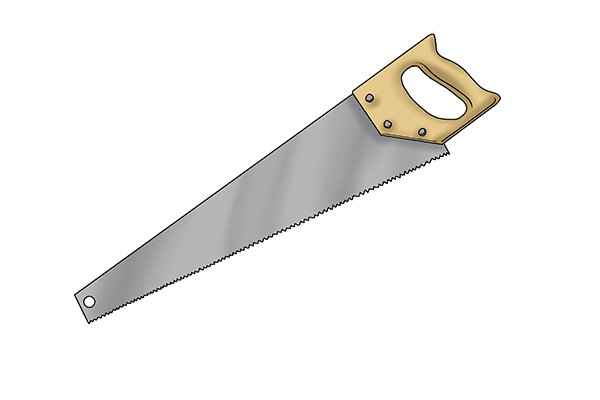

| Hand saw – preferably coarse toothed | |||

| Vice | |||

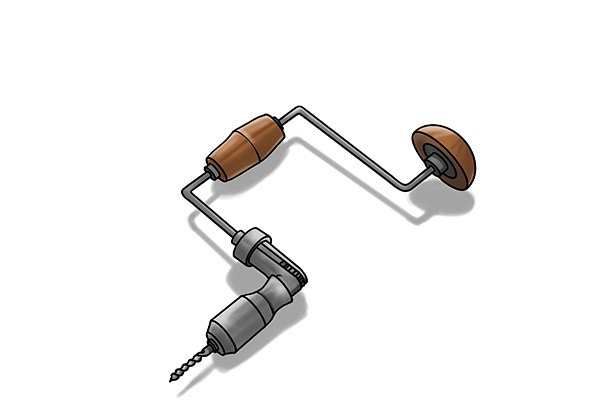

| Drill | |||

| 7mm (¼") drill bit | |||

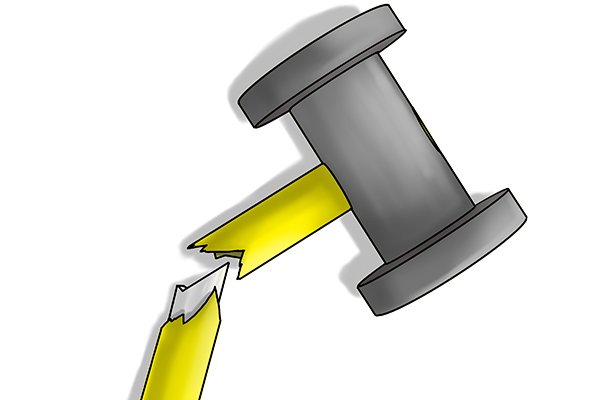

| Hammer | |||

| Sandpaper – Fine grain | |||

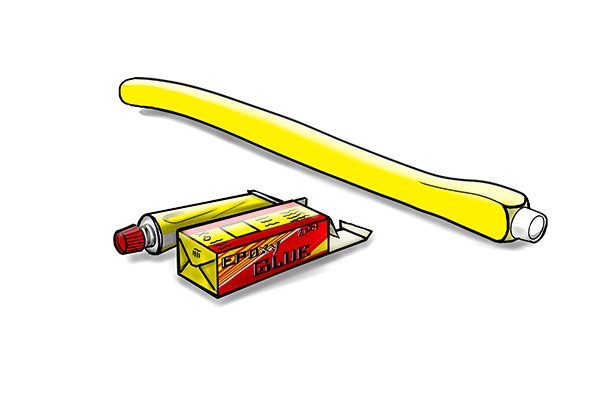

| Replacement handle kit – Containing a handle and two part epoxy mucilage | |||

| Caulking cord | |||

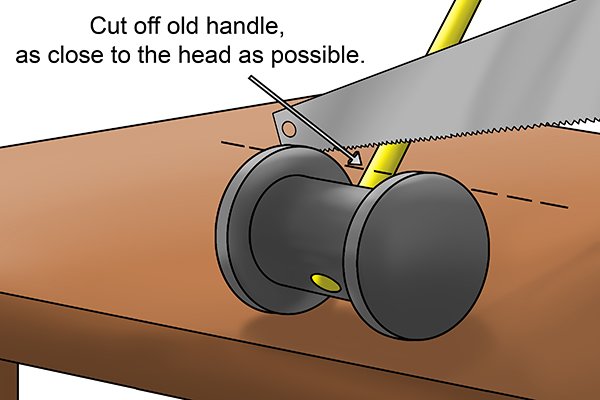

| Footstep 1 – Remove broken maul handleUse a handsaw with a class blade (bigger, rougher teeth do a much quicker job than that of fine teeth) to cutting away any remaining cleaved maul handle on the underside of the head. | |||

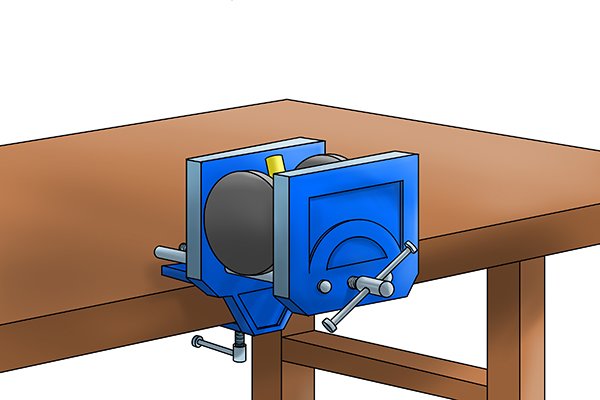

| Pace 2 – Support maul headPlace the tool head in a vice if you have access to one. | |||

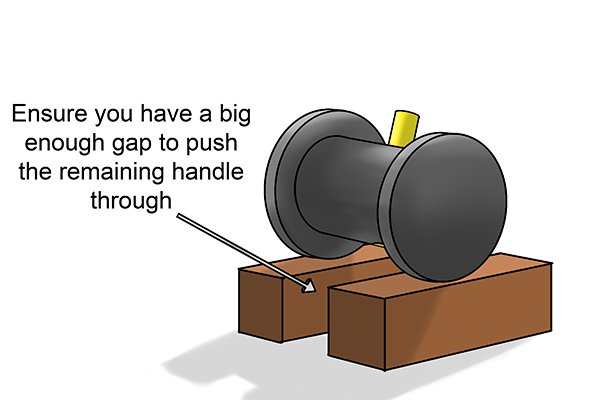

| If not, put the head on 2 solid surfaces with a gap between them, and from the superlative down, using the hammer and old maul handle every bit a punch, knock out the remaining handle. This should be done in the same management every bit the old handle would have been inserted. | |||

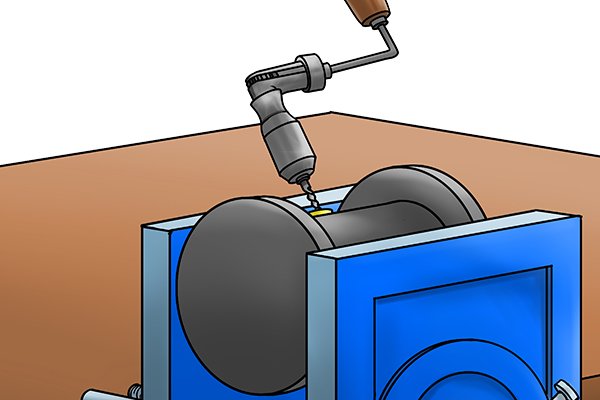

| Pace 3 – Drill into maul handleThis may well become to plan, but if the remaining handle is in likewise tight then it will require some help. Taking the drill and flake, drill holes in the fibreglass, either through the top or the underside, starting with one in the centre and a few around the edges equally this should help release the pressure holding the fibreglass in place, gear up to knock out. | |||

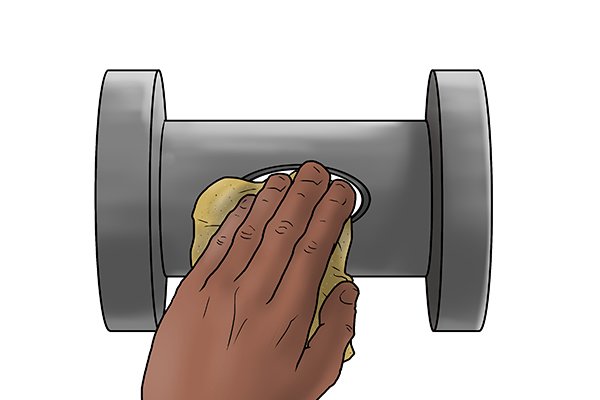

| Step iv – Make clean with sandpaperUtilise the sandpaper to clean out any remaining debris in the eye, from the previous maul handle. This will also provide a rough surface for the epoxy mucilage to bond to. | |||

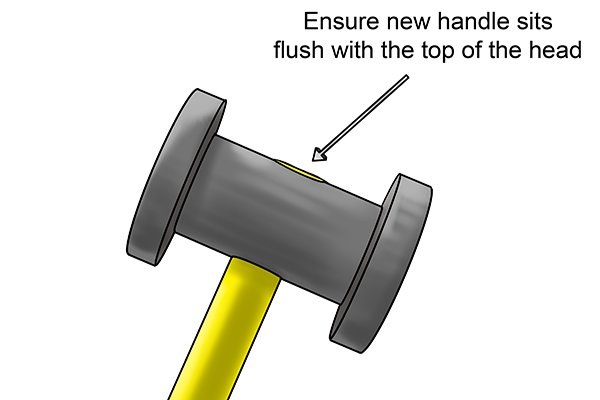

| Footstep v – Insert new fiberglass maul handleInsert the bottom of the new handle so that the cease sits affluent with the top of the head. | |||

| Step vi – Seal openingUsing the caulking string (a putty type substance provided in your kit), seal effectually the handle where it meets the underside of the maul head. This stops the epoxy glue from leaking out before it dries. | |||

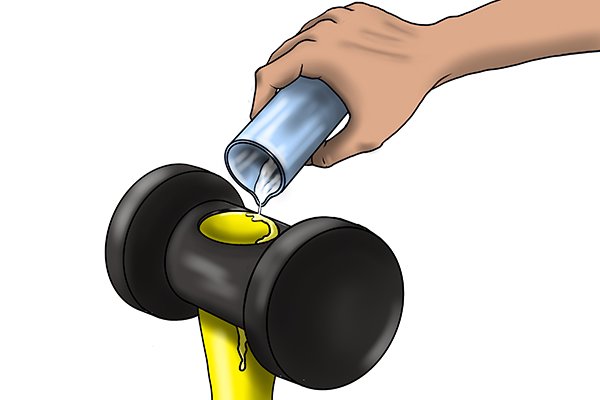

| Pace 7 – Mix and check sealHave the epoxy resin and mix both parts together every bit stated in the instructions. Cascade in a little of the resin showtime to check the seal. Should the caulk seal leak, you lot will lose all of your resin! To prevent leaking, push the putty further upwards into the middle. | |||

| Step 8 – Cascade and allow to hardenOnce the seal is secure, pour the resin, from the summit, into the gap between the head and the maul handle. Allow the epoxy resin to harden for the full amount of time, as stated in the instructions. If it does not set correctly, the maul may exist unsafe to use. | |||

| This fitting process should only be carried out past a competent person. | |||

Source: https://www.wonkeedonkeetools.co.uk/fencing-maul/how-do-you-repair-a-fibreglass-maul-handle

Posted by: kernlabon1943.blogspot.com

0 Response to "How To Repair Fiberglass Axe"

Post a Comment